Grinding Experts

Consistency. Speed. Precision. With over 10,000 sq. ft. of advanced manufacturing space and more than 75 state-of-the-art machines, we set the standard for quality and turnaround time—proving why we’re one of the best machine shops in the industry.

The Raymac Advantage

Discover what sets Raymac Grinding apart and why we’ve been an industry leader for decades. Download our PDF brochure below to learn more about our capabilities, quality control instruments, and commitment to on-time delivery.

Machines

Of Experience

Precision Grinding Services

Centerless Grinding

Fast and efficient processing for high-volume production

Delivers exceptional precision and consistency

Produces smooth, uniform surface finishes

Ideal for small or complex cylindrical parts

Ensures tight tolerances and repeatable accuracy

Quality Control

Commitment to achieving the highest precision and accuracy

Experienced technicians dedicated to quality craftsmanship

Advanced inspection tools and measuring equipment

Trusted brands including Pratt & Whitney, Mitutoyo, Deltronic, and Etelon

Rigorous quality control ensures flawless, reliable results

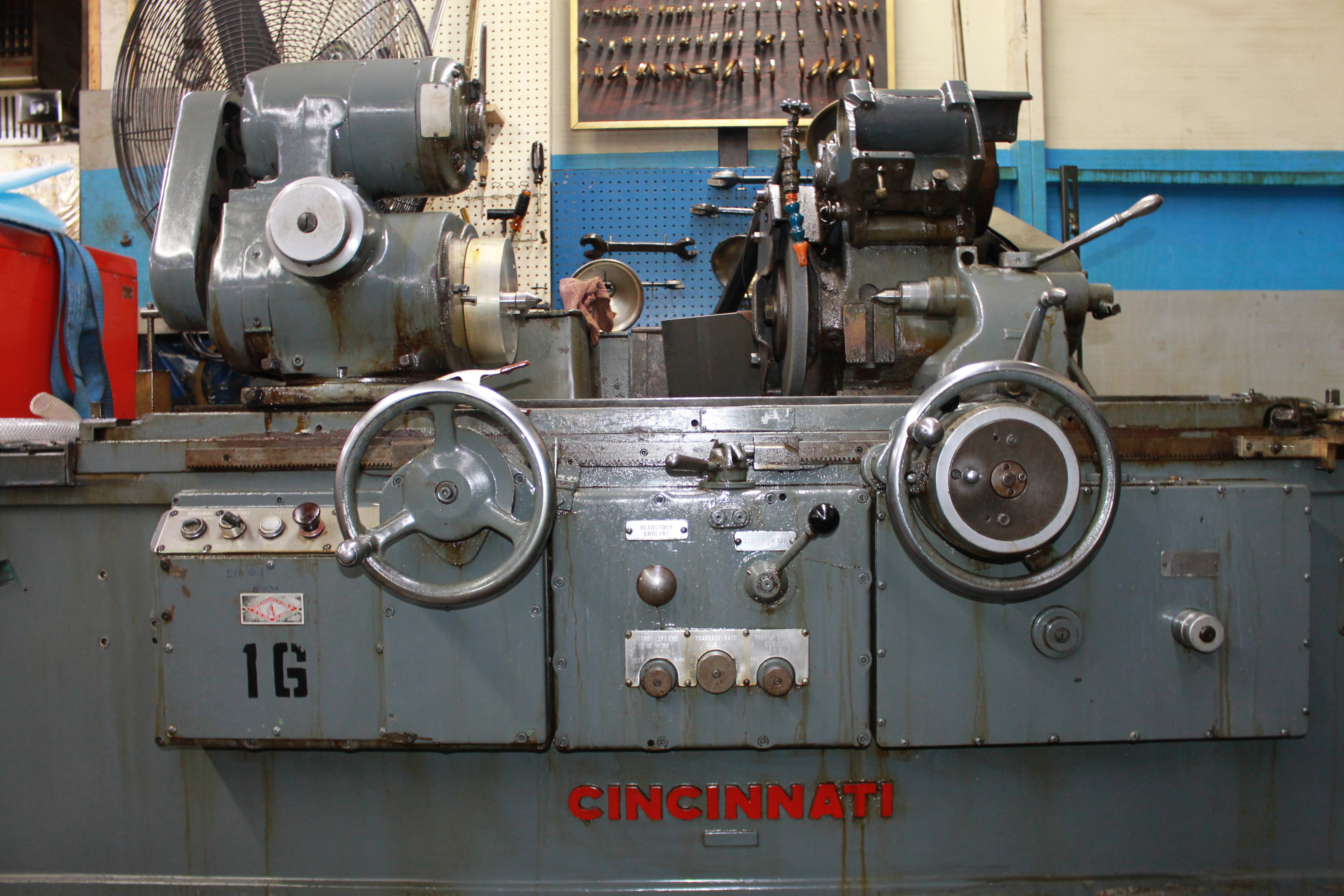

Outer Diameter Grinding

We specialize in precision grinding of external diameters to exact specifications

We achieve tight tolerances and superior surface finishes on cylindrical parts

Capable of handling a wide range of materials and part sizes

Utilizes advanced O.D. grinding equipment for accuracy and consistency

Ensures roundness, concentricity, and dimensional precision for critical components

Thread Rolling

Produces precise, uniform external threads with superior strength

Cold-forming process enhances tensile and shear durability

Wide selection of steel dies for various thread sizes and forms

Skilled machinists operating advanced in-feed thread rolling machines

Capable of small to high-volume production runs — from 1 to 250,000+ parts

Surface Honing

Achieves extremely tight and precise tolerances for critical components

Ideal for finishing cylinders, bores, and tubing with exceptional accuracy

Improves surface geometry and perfects surface finish for optimal performance

Utilizes precision honing techniques to remove minimal stock while enhancing finish

Ensures smooth, consistent surfaces that meet demanding industry standards

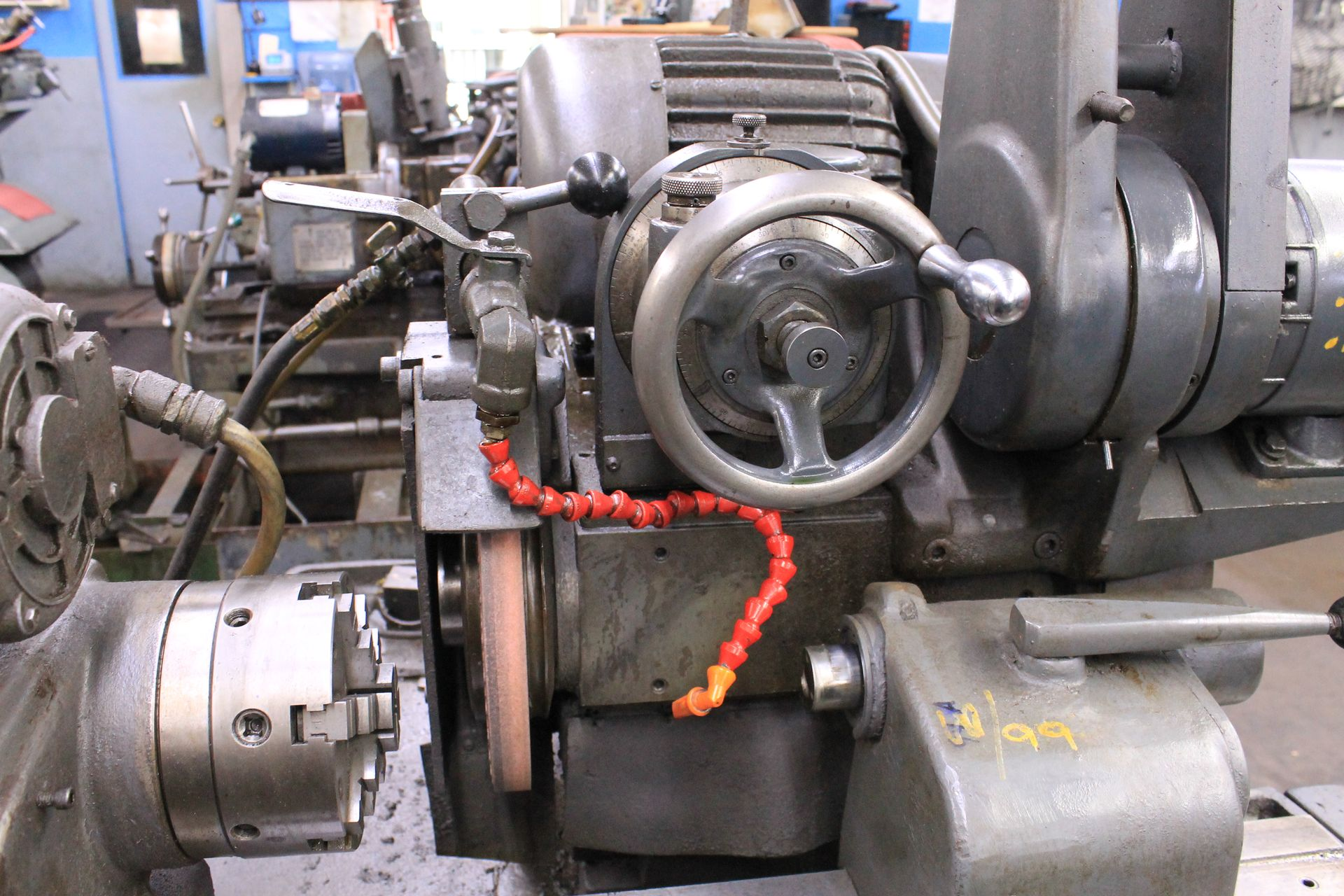

Inner Diameter Grinding

Precision grinding of internal diameters for complex components

Handles ferrous, non-ferrous, and specialty materials

Achieves tight tolerances and smooth surface finishes

Capable of working with deep bores and intricate geometries

Ensures consistent quality and accuracy across all production runs

Why Choose Us

Consistent Results

Every Time

From aerospace and medical to automotive and industrial applications, our services are trusted for their superior surface finish, precise diameter control, and costeffective turnaround.

Customer-Centric

Approach

We collaborate with you through every stage of the project, ensuring your vision is met with precision.

Tight Tolerances

and Quality Control

We maintain tight tolerances to ensure every part meets exact specifications. Our rigorous quality control process guarantees precision, consistency, and reliability in every project.

Ready To Get Started?

(714) 525-7793

The Industry Has Evolved

Raymac Grinding uses state-of-the-art, factory-calibrated machines to ensure precise, consistent, and high-quality results—every time.