Honing Metalworking

Everything you wanted to know

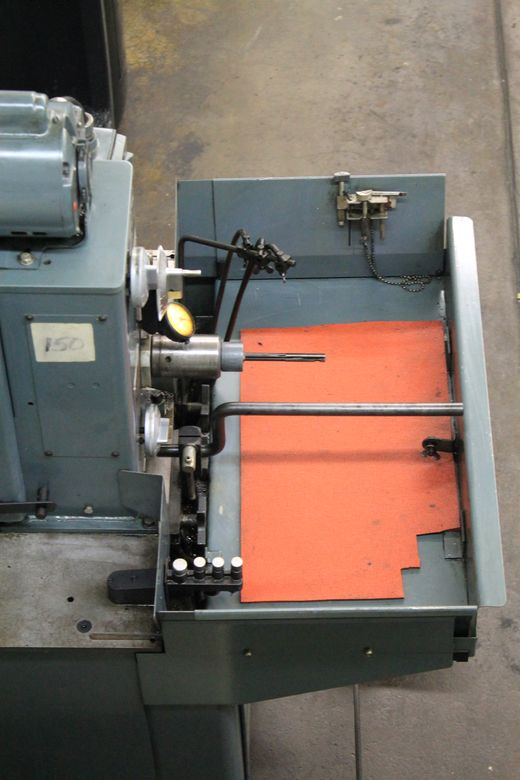

Honing

The most accurate precision process

Honing is used primarily on a workpiece that demands the most accurate, and stringent of tolerances such as cylinders of internal combustion engines. Honing also improves the geometric form of the surface and can perfect surface finish of tubing or bores. The hone is turned in the bore while being moved in and out of the workpiece, removing stock and providing a high-quality finish.

Material

Improving the geometric form of a surface

Honing is accomplished by abrasive stones of suitable grit, depending on the workpiece characteristic type. Raymac Grinding uses the highest quality honing stones for the best accuracy and finish. Finishing is done by rotating the proper honing tool against the work surface. The stock removal process takes out any flaked metal and provides the best possible finish pattern. In addition, honing will remove any out of roundness, axial distortion, and taper the workpiece may have.

Process mechanics

High performance workpieces

Honing is best suited for workpieces that demand the highest level of precision. The improved shape and finish after honing can provide the highest precision of the workpiece and quieter running. Raymac Grinding has provided honing services in Orange County for over 58 + years. We offer extremely accurate tolerances and quick turn around times.